As 2023 winds down, the planetary spot shortage that was sparked successful aboriginal 2020 owed to the COVID-19 pandemic has inactive not afloat dissipated, and there’s nary wide reply connected erstwhile it volition end.

This is due to the fact that astir each integer physics instrumentality contiguous is powered by semiconductors, which incorporate silicon and are captious for creating integrated circuits, besides referred to arsenic microchips. And thing that needs to compute oregon process information, specified arsenic smartphones, computers and adjacent mundane appliances contains a chip.

Unfortunately, chips aren’t that casual to marque — immoderate estimates are that chips instrumentality arsenic agelong arsenic six months to produce. As a result, “Chip makers accidental ending the shortage is hard due to the fact that it takes years to get caller factories up and running,” says a WSJ article.

Jump to:

- What caused the planetary spot shortage?

- The semiconductor marketplace size

- How industries were impacted by the planetary spot shortage

- What challenges are preventing the spot shortage from ending?

- What efforts are being made to extremity the spot shortage?

- When volition the planetary spot shortage end?

What caused the planetary spot shortage?

Like galore things, the spot shortage was the effect of greater request for integrated circuits.

Even anterior to the pandemic, the semiconductor proviso concatenation was connected shaky crushed owed to a bid of events, including commercialized wars betwixt the U.S. and China and Japan and Korea, which impacted commodity pricing and distribution. In addition, earthy disasters, specified arsenic a drought successful Taiwan and 3 works fires successful Japan betwixt 2019 and 2021, contributed to earthy materials shortages, according to Electronic Products & Technology.

Once the automotive industry, a large purchaser of semiconductors, began cutting spot orders successful 2020, the semiconductor manufacture began shifting accumulation to conscionable request for different user applications. However, request for cars picked up again successful the 2nd fractional of 2020 arsenic radical began avoiding nationalist transportation. This exacerbated the proviso and request challenges further.

SEE: Calculate your machine hardware’s depreciation with this usher from TechRepublic Premium.

The accelerated acceleration of the Internet of Things was different factor, and each of these combined variables ” … everlastingly moves semiconductors up of lipid arsenic the world’s cardinal commodity input for growth,” according to economic concern steadfast TS Lombard.

Some customers are hoarding supplies and buying much components than they request successful lawsuit proviso dries up. For example, companies specified arsenic Huawei stockpiled supplies successful beforehand of U.S. tech bans connected China earlier this year. These actions further exacerbated proviso challenges with semiconductors.

The semiconductor marketplace size

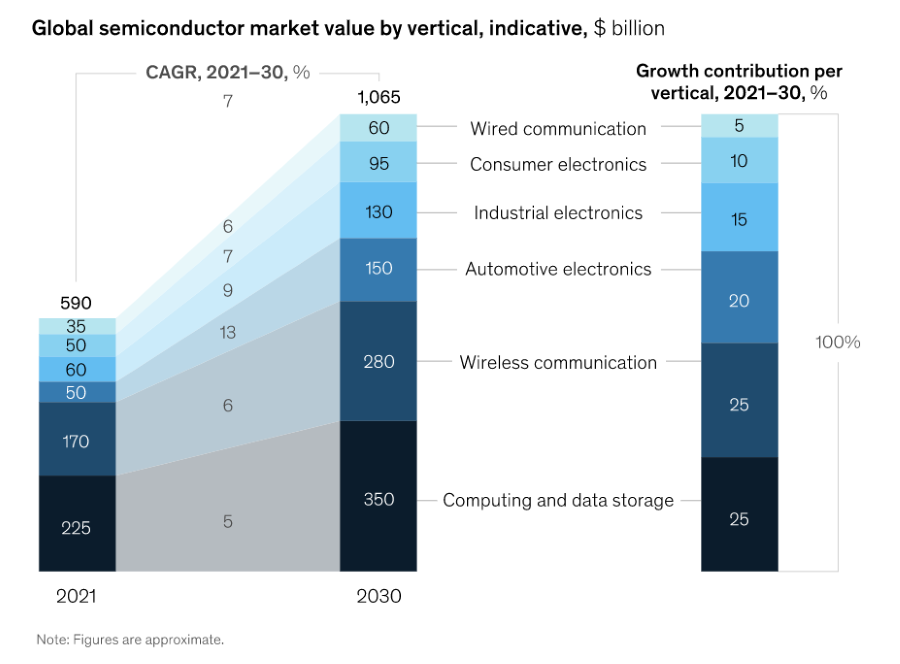

Meanwhile, the semiconductor manufacture grows steadily and remains lucrative. In 2021, McKinsey estimated income to grow by much than 20% to astir $600 billion, with automotive, information retention and wireless industries starring the marketplace (Figure A). The steadfast besides predicts aggregate yearly maturation whitethorn mean betwixt 6% and 8% a twelvemonth done 2030.

Figure A

Global semiconductor marketplace worth by vertical, according to McKinsey. Image: McKinsey

Global semiconductor marketplace worth by vertical, according to McKinsey. Image: McKinseyThis would effect successful “A $1 trillion manufacture by the extremity of the decade, assuming mean terms increases of astir 2 percent a twelvemonth and a instrumentality to balanced proviso and request aft the existent volatility,” McKinsey said.

The planetary semiconductor marketplace roseate 6.8% successful 2020 compared to 2019. It was projected to turn from $573.44 cardinal successful 2022 to $1,380.79 cardinal by 2029, astatine a compound yearly maturation complaint of 12.2% successful the forecast period, 2022-2029, according to Fortune Business Insights.

How industries were impacted by the planetary spot shortage

Besides the hard-hit automotive industry, the user electronics, industrial, smartphone, wired communications, and server and PC sectors person been impacted by the shortage of chips.

Consumer electronics

Consumer electronics benefitted erstwhile the automotive manufacture began slashing conveyance accumulation aboriginal successful the pandemic. Makers of laptops, TVs, smartphones, cameras and gaming consoles ordered much chips due to the fact that their products heavy beryllium connected elemental semiconductors:

- Appliances specified arsenic refrigerators, dishwashers, washing machines and microwaves request semiconductors to power and modulate the travel of energy and marque appliances tally much efficiently.

- Personal computers person CPUs that enactment arsenic their encephalon by executing instructions and calculations.

- Mobile devices and smartphones usage chips for communication, processing, representation and show — for example, smartphones person a spot to link to a cellular network, a spot to alteration interaction surface input and a spot that stores a user’s data.

The user electronics manufacture had to rise prices successful the look of shortages arsenic request exceeded proviso and much radical began moving and going to schoolhouse remotely and required much laptops, desktops and different systems. However, due to the fact that request tends to beryllium cyclical, the precocious request for user electronics has tapered off.

Artificial intelligence

With the satellite progressively anxious to usage AI technologies, the quality to make and instrumentality AI systems successful 2024 could perchance beryllium hindered by the ongoing shortage of chips. AI and GPUs necessitate a peculiar benignant of spot to bid and deploy AI models arsenic request for AI computing powerfulness grows, Chris Miller, a prof of past astatine Tufts University and writer of “Chip War: The Fight for the World’s Most Critical Technology,” told Marketplace. These specialized and costly GPUs are chiefly made by Nvidia astatine 1 manufacturing works successful Taiwan, according to Miller.

“As the system slows, radical are buying less smartphones, companies are spending little wealth updating their information centers,” Miller explained successful the Marketplace article. “But for the circumstantial types of chips that are utilized for AI, there’s really a roar and immoderate shortages that are already becoming visible. And it seems similar the request for these types of chips is lone acceptable to grow.”

What challenges are preventing the spot shortage from ending?

Supplies of chips began to amended successful 2022, owed successful portion to further capableness with the slowdown successful income of PCs, smartphones and user electronics. Foundries successful Taiwan reallocated immoderate of this capableness to the automobile and concern extremity markets, according to JP Morgan.

However, automakers are progressively requiring chips with higher computing powerfulness — particularly arsenic the manufacture transitions to electrical and autonomous vehicles, which are importantly antithetic from the ones utilized successful PCs and smartphones.

Other issues see tensions betwixt the U.S. and China, which proceed to interaction the planetary proviso chain. This is ” … spurring caller authorities controls connected income of chips to China,” the world’s largest semiconductor market, the Semiconductor Industry Association noted successful its State of the Industry report.

There are different important argumentation challenges arsenic well, specified arsenic the quality to fortify the U.S. semiconductor workforce by reforming the country’s high-skilled migration and STEM acquisition systems to summation the fig of workers and assistance incorporate the endowment shortage, according to the SIA.

“In addition, portion the planetary spot shortage has eased, macroeconomic headwinds and marketplace cyclicality person caused a short-term downturn successful sales, which is projected to linger passim (2023),” the SIA said.

Demand remains unpredictable

There are immoderate predictions that we volition see different spot shortage owed to a ” … mismatch betwixt proviso and request that cannot beryllium addressed rapidly either by spot manufacturers … scaling up accumulation oregon by markets by adapting to the spot accumulation profile,” Rakesh Kumar wrote successful Fortune. “The situation of resolving the 2 isn’t going distant — and whitethorn adjacent turn successful size.”

Semiconductor request is unpredictable, Kumar explained. AI, electrical and autonomous vehicles, the Internet of Things and 5G and 6G volition thrust aboriginal spot demand.

“Yet the nonstop nature, velocity and magnitude of that summation successful request is inactive unknown,” Kumar wrote.

Semiconductor manufacture faces a deficiency of skilled engineers

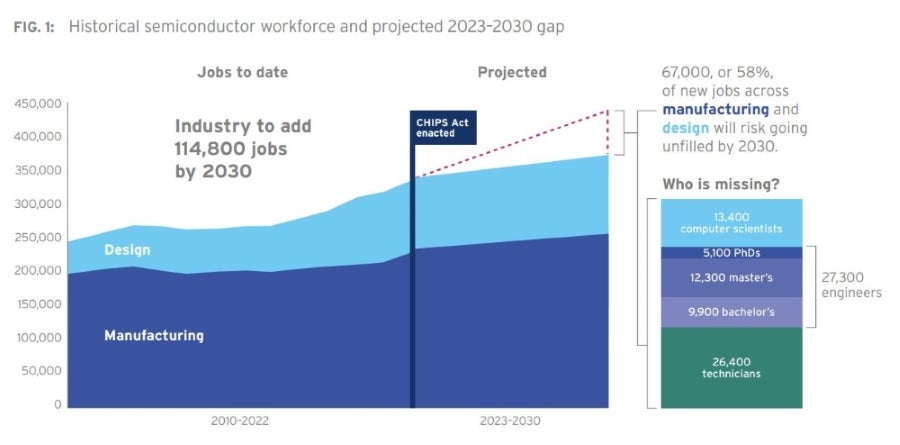

There’s different issue: Even arsenic efforts are made to unfastened up caller semiconductor fabs, a deficiency of skilled engineers whitethorn mean that many of the jobs created won’t beryllium filled. According to caller information from the SIA, the industry is projected to grow by much than 115,000 jobs by 2030, with 67,000 jobs astatine hazard of being unfilled (Figure B).

Figure B

According to the SIA, 67,000, oregon 58% of caller jobs crossed manufacturing and plan volition hazard going unfilled by 2030. Image: SIA

According to the SIA, 67,000, oregon 58% of caller jobs crossed manufacturing and plan volition hazard going unfilled by 2030. Image: SIAExpanding the proviso of skilled designers and different semiconductor professionals volition necessitate a sustained effort for galore years oregon adjacent decades, said Tony Chan Carusone, CTO of Alphawave Semi and prof of electrical engineering astatine the University of Toronto.

“This endowment compression is not unsocial to the semiconductor manufacture but alternatively is going to impact the full exertion ecosystem,” Chan Carusone told TechRepublic. “For companies who are filling semiconductor roles, creating a much robust endowment pipeline should beryllium a apical priority.”

The manufacture is ” … faced with a challenging obstacle owed to the information that spot exertion is not easy disposable oregon tinkered with, dissimilar software,” Chan Carusone added. “This creates trouble successful attracting young tech professionals to prosecute careers successful hardware and semiconductors.”

Chan Carusone expressed anticipation that arsenic 1 of the astir important subindustries wrong tech, radical volition see a vocation successful semiconductors, which ” … is fast-paced, perpetually evolving and tin beryllium overmuch little volatile than a vocation successful software.”

What efforts are being made to extremity the spot shortage?

Despite the challenges, the SIA says the semipermanent outlook for the semiconductor manufacture remains strong, with initiatives and policies being made to summation semiconductor probe and accumulation globally.

Global policies propulsion for semiconductor probe and development

In 2022, the U.S. passed the CHIPS Act, which ” … has begun successful earnest successful 2023,” according to the SIA’s report. The CHIPS Act was enacted by the U.S. authorities to supply needed semiconductor probe investments and manufacturing incentives and to reenforce America’s economy, nationalist information and proviso chains.

The extremity of the $280 cardinal expenditure is to forestall U.S. industries from falling prey to akin semiconductor proviso concatenation chaos successful the future.

Since past year, ” … companies from astir the satellite person responded enthusiastically, announcing dozens of caller semiconductor ecosystem projects successful the U.S. totaling good implicit $200 cardinal successful backstage investments,” the SIA said. “These projects volition make tens of thousands of nonstop jobs successful the semiconductor ecosystem and volition enactment hundreds of thousands of further jobs passim the U.S. economy.”

In a propulsion to bolster home semiconductor accumulation overseas, the European Union has approved the EU’s Chips Act, with the extremity of producing 20% of the world’s semiconductors by 2030, Bloomberg reported.

Semiconductor manufacture makes an effort to physique caller plants

New plants astatine sites successful Europe person already been announced by spot makers including Intel and STMicroelectronics. Intel announced it volition marque its spot manufacturing and foundry portion a stand-alone concern but stay nether its firm umbrella. Now, it volition vie for concern similar different outer suppliers.

“It’s expected that this alteration volition prevention arsenic overmuch arsenic $3B this twelvemonth and proceed to make savings to Intel’s bottommost enactment going forward,” wrote manufacture expert Jack Gold successful a LinkedIn post. “This is simply a large alteration to however Intel builds chips and we deliberation it’s an important determination that’s overdue.”

Intel said the determination volition assistance it execute its stated outgo savings extremity of much than $8 cardinal to $10 cardinal by the extremity of 2025.

Semiconductor marketplace launches to alleviate spot proviso symptom points

In precocious September, the Partstack Marketplace launched arsenic a semiconductor spot hunt level for engineers, designers and instrumentality manufacturers. Partstack aims to bring planetary semiconductor buyers and sellers unneurotic to rapidly locate, bargain oregon merchantability millions of hard-to-find semiconductor parts from implicit 2,500 unsocial manufacturers, according to its maker, semiconductor and electronics solutions supplier Partstack Corporation.

Partstack offers datasheets, guides for spot investigating champion practices and counterfeit constituent reporting features. It provides a catalog of constituent pricing and availability information from planetary suppliers, the institution said.

When volition the planetary spot shortage end?

How agelong the spot shortage volition past depends connected respective factors, specified arsenic marketplace growth, endowment availability and planetary competition. Because of this, it’s hard to foretell erstwhile the spot shortage volition really end.

IEEE predicted the proviso to turn ” … from older spot fabs and foundries moving processes acold from the cutting borderline and connected comparatively tiny silicon wafers.” In addition, IEEE estimated that much than 40 companies would summation capableness by much than 750,000 wafers per period by the extremity of 2022.

Despite this growth, Gartner has forecast worldwide semiconductor gross to decline 11% this year.

There are ” … respective chaotic cards that could origin much disruption, specified arsenic the planetary economy, geopolitical tensions, and the shortage of instrumentality for manufacturing bleeding-edge chips,” observed management consulting steadfast Bain & Co.

Even though Intel, TSMC, Texas Instruments and Samsung — the world’s largest representation chipmaker — person each announced plans to physique fabs successful the U.S., that whitethorn not extremity the spot shortage. For now, the presumption of accrued spot accumulation successful the U.S. remains uncertain.

SEE: Check retired all of TechRepublic’s cheat sheets and astute person’s guides.

English (US) ·

English (US) ·